Personalise your garments with ease!

Direct-to-garment printing has been catching up fast as there is a need for not only customisation but also personalisation of garments as well. It offers a new avenue for small print shops.

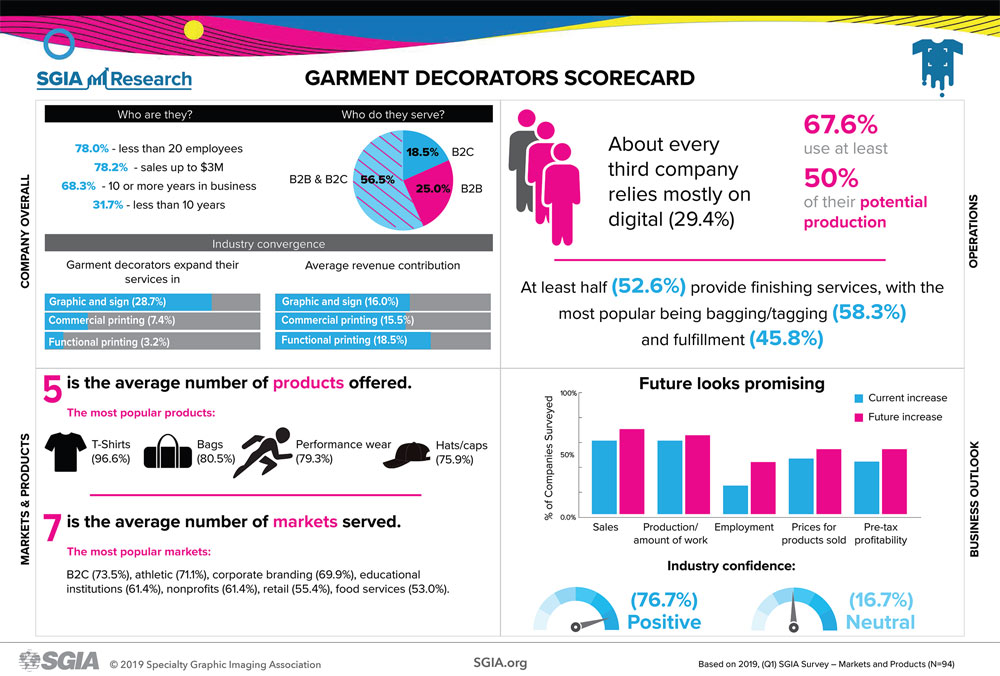

According to the SGIA’s Industry Benchmarking Reports, 78% of garment decorators have less than 20 employees, 78.2% have sales up to $3 million and 68.3% have 10 or more years in business (31.7% — less than 10 years old). Talking about the business, they cater to B2C — 73.5%, Athletic — 71.1%, Corporate Branding — 69.9%, Educational Institutions — 61.4%, Non-profits — 61.4%, Retail — 55.4% and Food Services — 53.0%. The most popular products include T-Shirts (96.6%), Bags (80.5%), Performance wear (79.3%) and Hats/caps (75.9%). Mass customisation, increased personalisation, and environmental benefits are fueling the growth of short-run print on demand.

According to the SGIA’s Industry Benchmarking Reports, 78% of garment decorators have less than 20 employees, 78.2% have sales up to $3 million and 68.3% have 10 or more years in business (31.7% — less than 10 years old). Talking about the business, they cater to B2C — 73.5%, Athletic — 71.1%, Corporate Branding — 69.9%, Educational Institutions — 61.4%, Non-profits — 61.4%, Retail — 55.4% and Food Services — 53.0%. The most popular products include T-Shirts (96.6%), Bags (80.5%), Performance wear (79.3%) and Hats/caps (75.9%). Mass customisation, increased personalisation, and environmental benefits are fueling the growth of short-run print on demand.

Direct-to-garment (DTG) printing…

Direct-to-garment printing or garment decorators refer to businesses that add to or alter clothing after it’s been manufactured. Most popularly, it is used for T-shirts for branding purpose. This has been a game changer ever since it was launched. Earlier, custom design was done by either digital transfer paper or screen print.

Digital Transfers use designs printed out on a specialty paper via a standard desktop inkjet or laser printer. The transfer paper is covered with a polymer (AKA adhesive) that glues the ink to the top of the shirt. While, Screen printing is a traditional printing method where ink is dropped down on garment where the design is. The process is complex as you need different screens for each colour you want to print. Hence, it is time consuming and expensive.

While, the DTG Printer is a cheaper and faster way to print onto garments. It uses textile water-based ink that has chemical binders that allow the ink to remain on the garment without a polymer being applied to the top of the shirt like a transfer. The ink is then cured to the garment using either a heat press or a textile conveyor dryer. It is easy, and can print short run personalised garment in just a few minutes.

Different DTG printers available…

Brother, the pioneers in the DTG printers, offers GTX Direct to Garment printer. With a print resolution of 1200 x 1200 dpi combined with cutting edge Innobella inks, designs can incorporate the entire color spectrum and even minute details will print with fantastic clarity. With the white ink channels stacked right behind the CMYK channels, one can print almost anything in a single pass. Being easy to use and maintain is one of the most important features of the GTX. The standard wet capping station minimises clogged nozzles and the white ink circulation system keeps the system primed and ready to print. The GTX is more than a t-shirt printer. The large gap between the print head and the substrate means one can easily print over seams, across zippers and on top of pockets. With a maximum print size of 16” x 21”, designs can be bigger and bolder than ever. Extra thick items are no problem thanks to the adjustable platen height system. It uses GTX and Innobella Inks, ensuring durability and washability.

Brother, the pioneers in the DTG printers, offers GTX Direct to Garment printer. With a print resolution of 1200 x 1200 dpi combined with cutting edge Innobella inks, designs can incorporate the entire color spectrum and even minute details will print with fantastic clarity. With the white ink channels stacked right behind the CMYK channels, one can print almost anything in a single pass. Being easy to use and maintain is one of the most important features of the GTX. The standard wet capping station minimises clogged nozzles and the white ink circulation system keeps the system primed and ready to print. The GTX is more than a t-shirt printer. The large gap between the print head and the substrate means one can easily print over seams, across zippers and on top of pockets. With a maximum print size of 16” x 21”, designs can be bigger and bolder than ever. Extra thick items are no problem thanks to the adjustable platen height system. It uses GTX and Innobella Inks, ensuring durability and washability.

Epson offers SureColor SC-F2000, which uses Epson’s UltraChrome DG ink which works with the PrecisionCore printhead to deliver the ultimate in print quality with an extremely high resolution of 1440 x 1440 dpi. Epson UltraChrome DG Ink is a water-based pigment CMYK ink manufactured to deliver precise, repeatable performance and superior image quality. Inks are developed together with the printhead technology to ensure optimum compatibility for clean, uniform and accurate colours for garments with amazing finishes, as well as to prevent nozzle clog. Printed designs are stretch resistant and free from the tacky feeling commonly present in other printed shirts.

RICOH offers Ri 100 which prints images directly onto clothing fabrics using state-of-the-art DTG technology. The RICOH Ri 100 can fit into a space as small as 399 x 698 mm, making it one of the smallest DTG printers. The printer and its finisher can be stacked to maximise functionality without sacrificing space.

DTG: the way ahead…

There are lot of opportunities ahead for DTG print service providers as there will be an increasing demand for customised and personalised prints on garments.

–Varsha Verma

Comments are closed.