Hybrid finishing technology: make the right move

Print shops shy away from investing in finishing equipment due to lack of space and budget. But, hybrid finishing technology not only saves floorspace but also makes finishing easy, besides giving an option to diversify. With this, even sign-makers can diversify into packaging.

Finishing is an important part of any print job. Earlier, smaller print shops did not wish to invest in multiple finishing equipment due to lack of space and budget. But, with hybrid finishing technology, which route, cut and slice, not only saves floorspace but also makes finishing easy.

Let’s look at various hybrid printing machines available in the market.

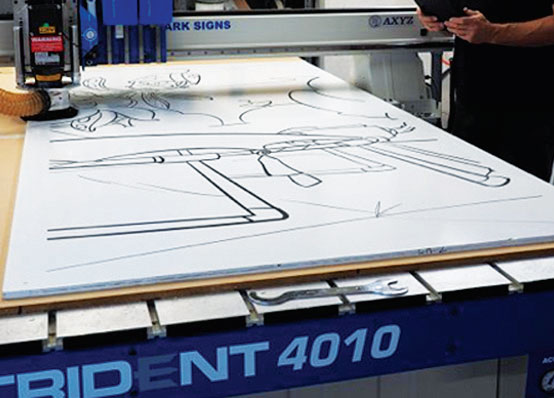

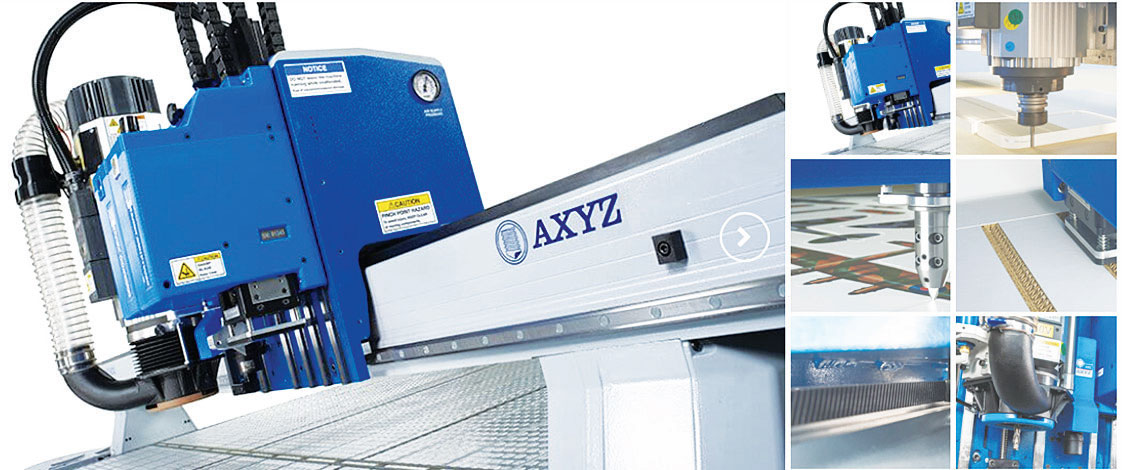

Trident from AXYZ Automation

Digital finishers are being asked to do more including routing aluminium and acrylic and cutting/trimming paper, vinyl, foam board, coroplast, styrene and rubber. As a result, AXYZ Automation developed a CNC router that meets the traditional demands of the digital finishing industry while delivering overwhelming power to take on broader projects.

Trident is a versatile router-knife combination, which can handle widths from 1524mm to 3270mm and lengths from 1219mm to 15m. It has hybrid triple head configuration and finds applications in graphics & print finishing (cut-to-print using multiple tools for all materials), signmaking (all types of 2D and 3D signs in woods, metals and plastics), foam packaging (2D and 3D processing with router and knife tools), and point of purchase (display stands, fixtures and fittings).

Processing a wide range of materials requires more than one cutting head. The Trident combines three different cutting technologies to provide maximum versatility by offering a choice of routing spindle and two knives which can be either tangential, oscillating or a combination of both. The benefits include hybrid triple head on narrow carriage for small footprint, high-power router for fast processing of tough materials, tangential and oscillating knife tools for all flexible and semi-rigid materials and high gantry clearance for processing of materials up to 120mm thickness.

What’s more? Trident is compatible with a multitude of optional enhancements to customise your CNC router and improve accuracy, flexibility, productivity and quality.

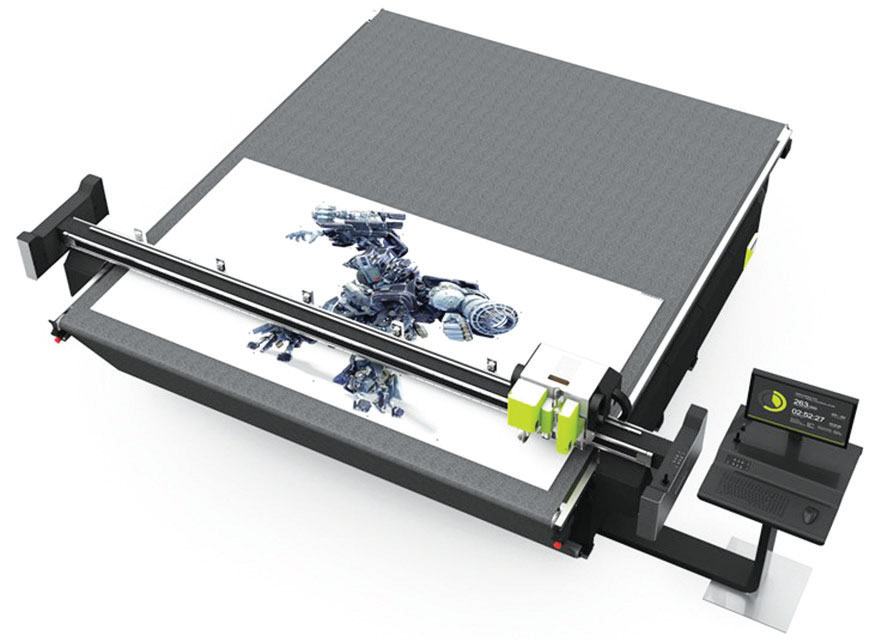

Esko Kongsberg C series

The Esko Kongsberg C table is designed to keep up with the faster, wider printers of today and tomorrow. Exceeding the standards in versatility, precision and productivity, it has everything that Kongsberg tables are noted for, and more. It is the very first multifunction super-wide digital finisher for signage, display and packaging applications.

The Kongsberg C is designed to handle all types of substrates, thick to thin. It is the only super-wide finisher to offer a 3kW continuous duty high-performance milling unit. The Kongsberg C delivers the same performance every time, even on the most demanding materials or for the most complex jobs. Besides, it offers size and productivity simultaneously, eliminating the need to own dedicated digital finishers for different applications. The Kongsberg C offers a full solution consisting of hardware, software, bits & blades, and services.

The Kongsberg Automate board feeder and stacker is easy to use pallet-to-pallet solution. It feeds corrugated, paper core boards and plastics quickly and accurately from pallet with 2 feed cycles per minute in a continuous material flow. There are no delays loading and unloading boards from the table, so the table is utilized optimally.

With stack height at 915 mm/36 in and quick automatic load cycles, it is the optimal solution for short run production on all typical packaging and display materials.

The optional Underside Camera scans the sheet from below (the print side) and automatically locates the registration marks, barcodes and the corner of the sheet – saving between 20-30 minutes per set up!

Graphtec F-Mark Plus

automatic sheet fed cutting & creasing system

Keith Electronics offers Graphtec machines in India. The Graphtec F-Mark Plus automatic sheet fed cutting & creasing system provides a larger media size capability than the standard F-Mark and also offers the ability to crease media with the addition of a creasing tool. It uses a Graphtec CE6000-60 Cutting Plotter, automatic Media Feeding Arm With Vacuum Suction Cup and includes Media Catch Tray. It can handle max media size of 520mm x 700mm and can hold up to

200 sheets (35mm max stacked media height), besides allowing for automation in a smaller scale workplace.

The machine features die-cutting, kiss-cutting, perforation-cutting and media creasing (with optional creasing tool).

The right move…

Apart from the obvious benefits of saving floorspace and eliminating the need to invest in more than one machines, it makes sense to opt for hybrid finishing machinery as this can help a print shop expand into new markets.

–Varsha Verma

Comments are closed.