“Make you company more competitive and profitable with Yoco Cold Foil Unit”

says Rajesh Aggarwal of SRK Technology Pvt Ltd in conversation with Print & Publishing.

What is cold foil printing?

What is cold foil printing?

Rajesh: Cold foil printing, also known as cold foil stamping, is a modern method of printing metallic foil on a substrate in order to enhance the aesthetics of the final product. Cold foil printing can be done in two ways: online and offline.

Inline process on the 7 or 8-colour offset printing machine, followed by printing by UV inks: From the first unit, glue is applied on the paper/board by printing plate while from the second unit, foil is transferred on the glued surface followed by printing on the metallic foil.

Offline process: It works on 2 colour offset printing machine.

From the first unit, glue is applied while the second unit applies

the foil. This cold foil sheet is later taken to 5/6 colour printing machine for printing.

Why there is so much need of cold foil in India?

Rajesh: Government of India has already started the process of ban on single use plastics in which polyester which is non bio-degradable product and metalized polyester which is widely used in lamination has to stop soon. It’s not an environment-friendly product and before year 2022, it’s production will be stopped.

What is the alternative to glitter and fancy looking cartons?

Rajesh: The answer is cold foil: in-line or offline. The look of carton is further enhanced as cold foil gives dot effect which was missing in metalized lamination. The effect is marvellous and printing quality is enhanced several times and it is environment friendly.

How does the Cold Foil by Yoco work?

Rajesh: In the first print unit, the adhesive is applied. A standard offset plate is used to apply the adhesive onto the paper / cardboard in the exact position where the foil has to be.

In the second printing unit, the foil adheres strongly and durably to the adhesive. The transfer of the sheet without contact inside the machine with aerodynamic air conveyors ensures a production without scratch, stain and imperfection.

Colour printing begins with the third printing group. Now the sheet with the adhesive and foil already applied, is now overprinted in line, in one pass, to get the laminated and printed product immediately. Coating should be applied as a protective layer.

The foil is available in different colours. The base foil is silver but, since silver is a neutral colour, almost all metallic effects, including golden shadows, can be achieved with CMYK printing on silver. Dark black can also be achieved by masking and then black printing on the masked part.

Colour effects are achieved using CMYK printing and then glossy or mat coat. You can also use the gold foil in the same way.

The cost is practically the same. There are also different types of holographic foil, including the rainbow foil being the most used.

However, you can easily use your machine under normal conditions if you do not need to print the foil. The changing times in this way are the same as those of a normal offset printing

You will only need to clean the first printing unit from the glue and for this job you will use the same solvents as the cleaning of the inking. For the foil you just have to cut the reel and rewind it up so it does not bother you.

With Cold Foil by Yoco, your company becomes more competitive and more profitable

Your new system allows you to:

– Increase sales and expanding the customer base, increasing their fidelity, thanks to the uniqueness of your production and the very low competition;

– eliminate additional labor costs and external resources;

– reduce operating costs;

– eliminate expensive foil board;

– take advantage of all-in-line processes.

What are the advantages of cold foil over hot foil?

Rajesh: Cold foil can be overprinted on high end customer’s products. It enables fine lines upto 0.05 mm, screens (from 25% to 70%) and solids. On most applications, cold foil is upto 30% lower in cost than hot foils. It can be used for very important pages with high request of register.

What is the USP of YOCO cold foil unit?

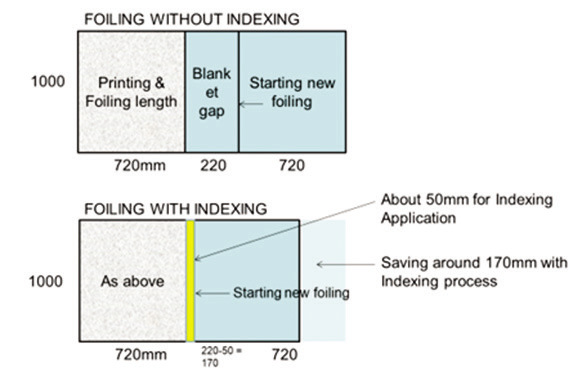

Rajesh: YOCO’s Indexing System allows you to index the blanket gap foil consumption to the printing length. They have built an Indexing System inside the cold foil unit so that the new lamination starts right at the end of the previous cylinder turn, using our special system. All at speeds of about 8,000 sheets per hour

As the blanket gap runs, the infeed rollers pull back a foil length equal to the blanket gap.

On which machines can YOCO be used?

Rajesh: Yoco Cold foil unit can be retrofitted on Heidelberg/KBA/Man Roland/Komori machines.